Brand: XURON

XURON's DTF Powder Shaker for Effortless Printing Preparation may be the tool that is ideal anyone trying to streamline their printing process. The item can certainly make yourself easier whether you are a professional printer or a hobbyist.

The DTF Powder Shaker was created to evenly circulate powder onto film sheets to help make top-quality that is certain. It really is incredibly easy to use. Just fill the shaker along with your DTF that is powder that is favorite the film sheet on the top and shake the container forward and backward. The powder will of times be evenly distributed through the film, making it prepared for printing.

This system was created to final, with durable materials that may stay the test of that time. The container is constructed of top-notch plastic that will not break or break effortlessly. The lid fits securely, preventing any powder from spilling away. It's the size that is perfect your publishing needs, easily stored for a shelf or in a drawer.

Not just is the DTF Powder Shaker user friendly and developed to last, it is also affordable. It really is a good investment that could save you money within the run that is long. By making sure your prints come out perfectly any right time, may very well not need to take your time or cash on reprints or mistakes. The DTF Powder Shaker is an efficient and solution this is certainly cost-effective your publishing needs.

Another feature this is certainly fantastic of DTF Powder Shaker is its versatility. It works with several DTF powders in the marketplace, and so the powder is selected by you which in fact works ideal for your requirements. This product is perfect for printing all sorts of designs, whether you're creating t-shirts which are custom stickers, or any other items.

60cm DTF machine | ||

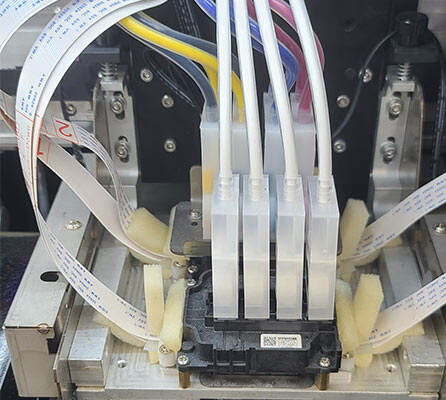

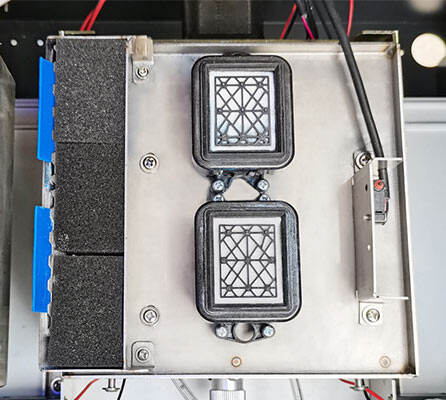

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

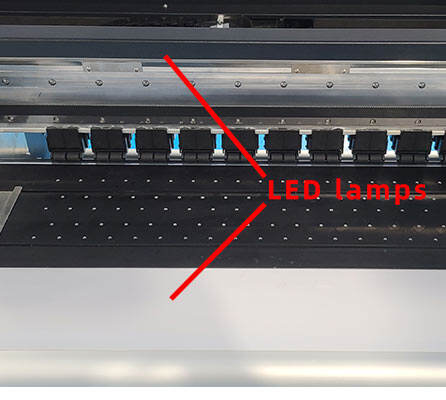

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

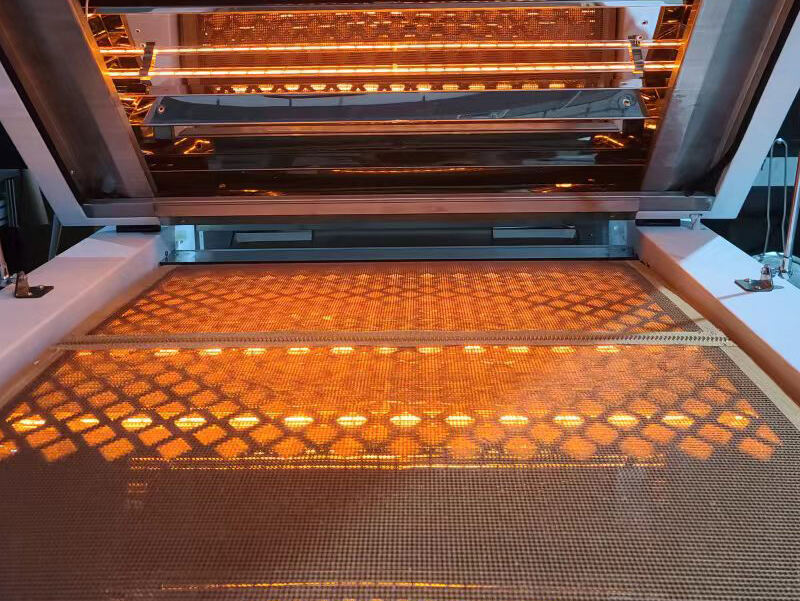

Shaking Powder | Motor vibration, automatic powder return-free | |

Heating Method | Back baking and front baking Fast constant temperature heating | |

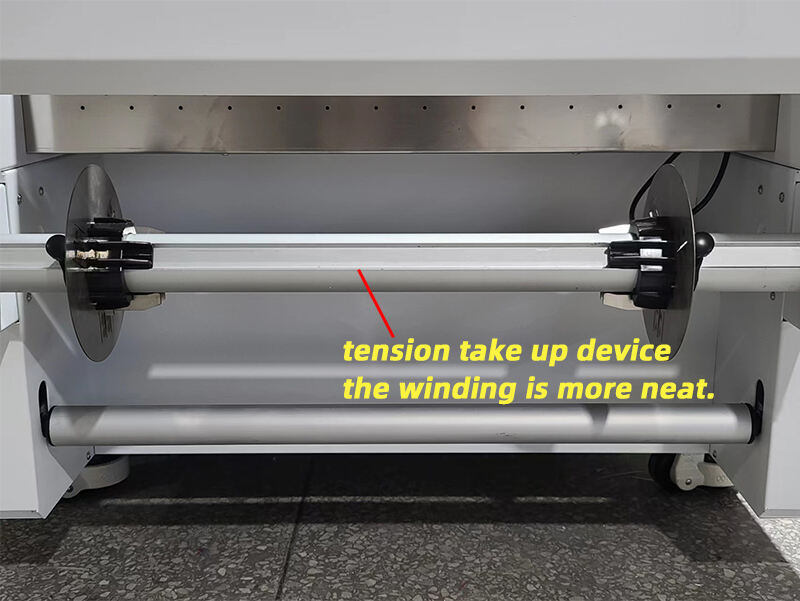

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

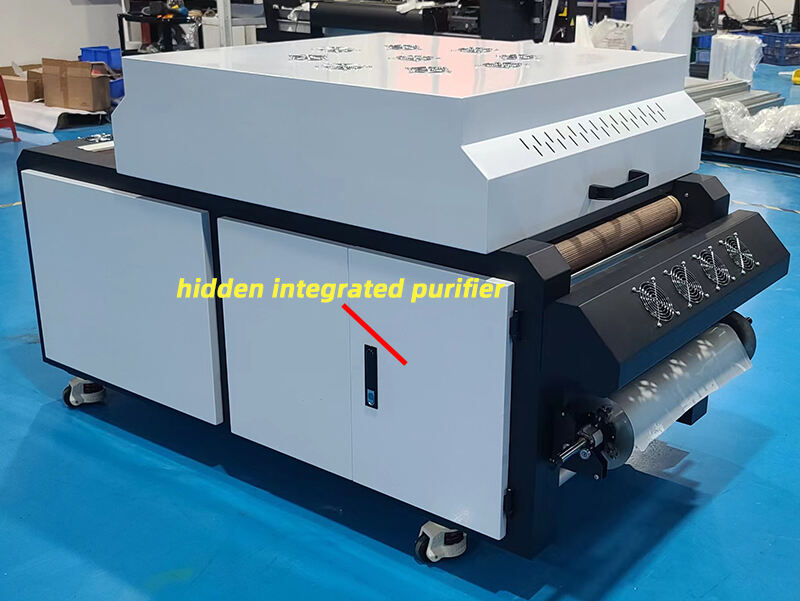

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |