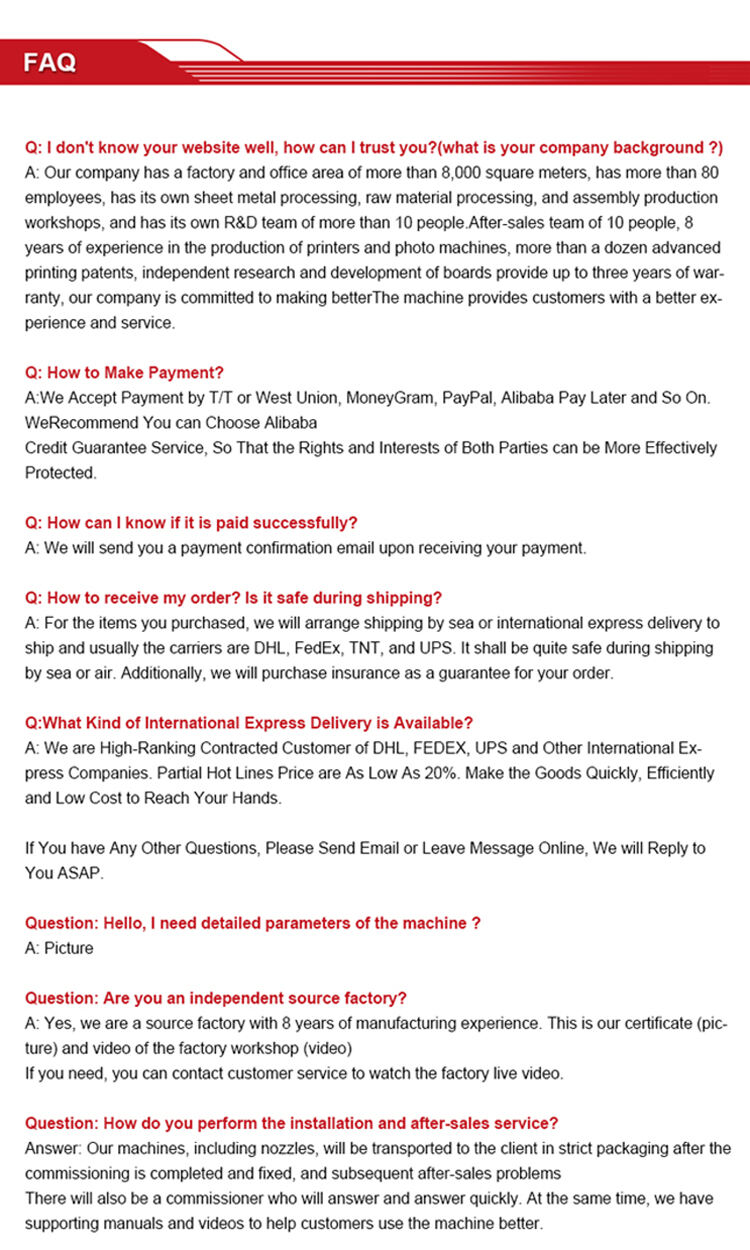

XURON

Presenting the DTF powder shaker machine, the addition that is latest to the XURON selection of printing solutions. Meant to streamline and simplify DTF publishing, this product will be the tool is certainly businesses are ideal to grow their publishing capabilities.

The DTF powder shaker device is actually a tight and device is efficient makes printing with DTF powder a breeze this is certainly absolute. This product guarantees top-notch prints each time having its level printer is advanced technology. Its right for an array of printer models, which makes it an addition is versatile any printing setup.

The shaker machine deals with the powder that is unique procedure that evenly distributes the DTF powder onto the transfer film, ensuring a frequent and printing is perfect. It eliminates the necessity for handbook shaking or spreading, that can easily be outcome and time-consuming in uneven publishing. Utilizing the DTF powder shaker device, you are going to create hundreds of prints quickly and effortlessly.

One of the many standout options that come with the DTF powder shaker machine is its user-friendly program. With only several ticks, it is an easy task to navigate its settings and personalize the settings to match your particular needs which are printing. The touchscreen display provides feedback is real-time the publishing procedure, ensuring you never skip a beat.

Furthermore, the DTF powder shaker machine is built to last. Its construction this is certainly ensures that are sturdy durability, also with heavy use. The equipment is also a task is easy keep, with easy cleansing procedures that may be performed in moments.

60cm DTF machine | ||

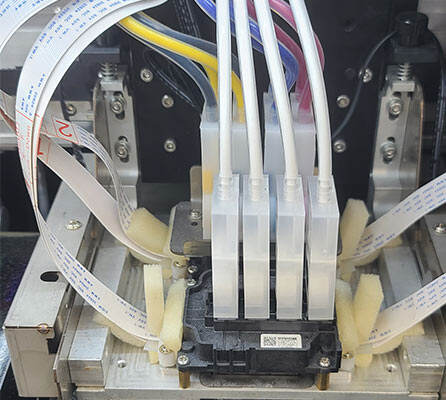

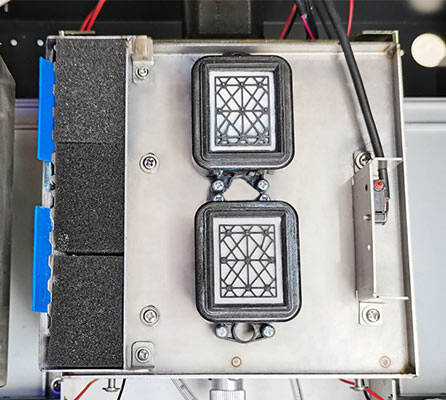

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

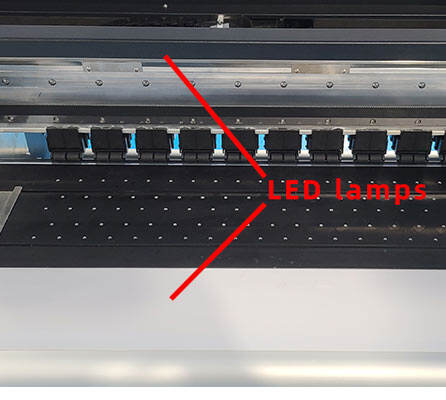

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

Shaking Powder | Motor vibration, automatic powder return-free | |

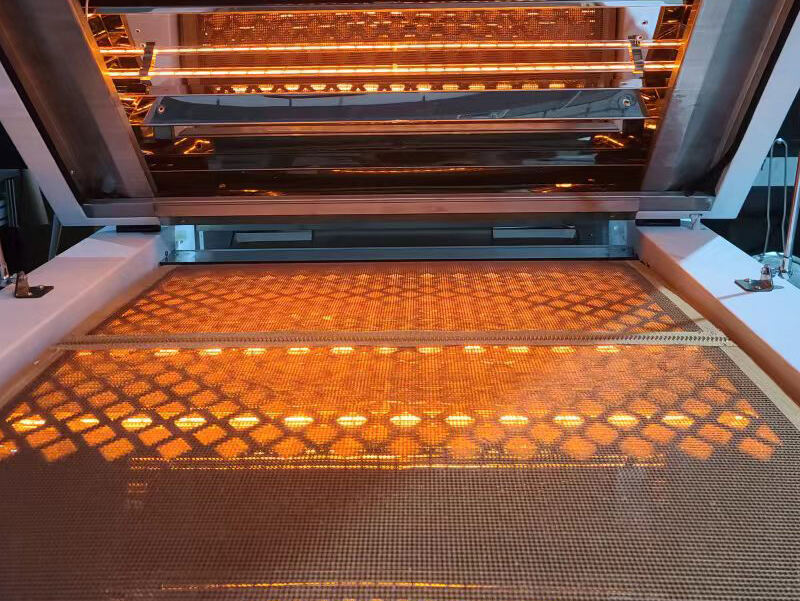

Heating Method | Back baking and front baking Fast constant temperature heating | |

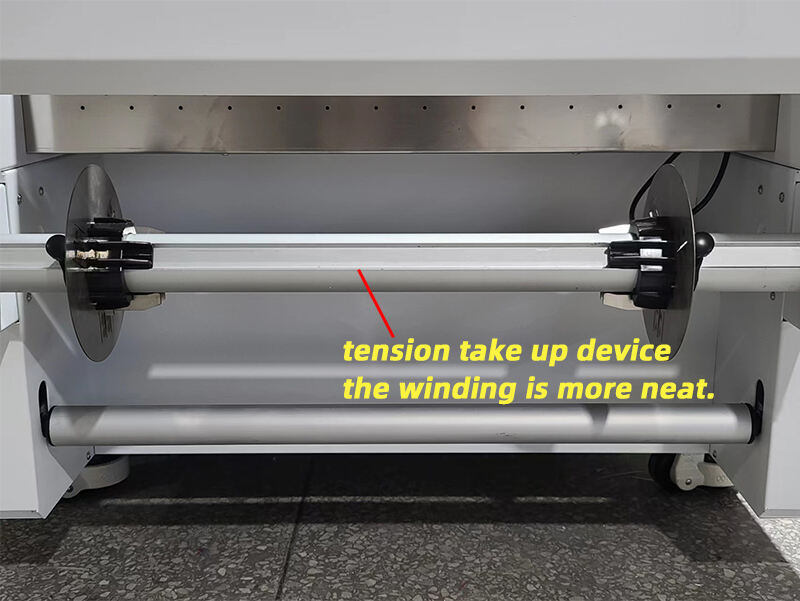

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

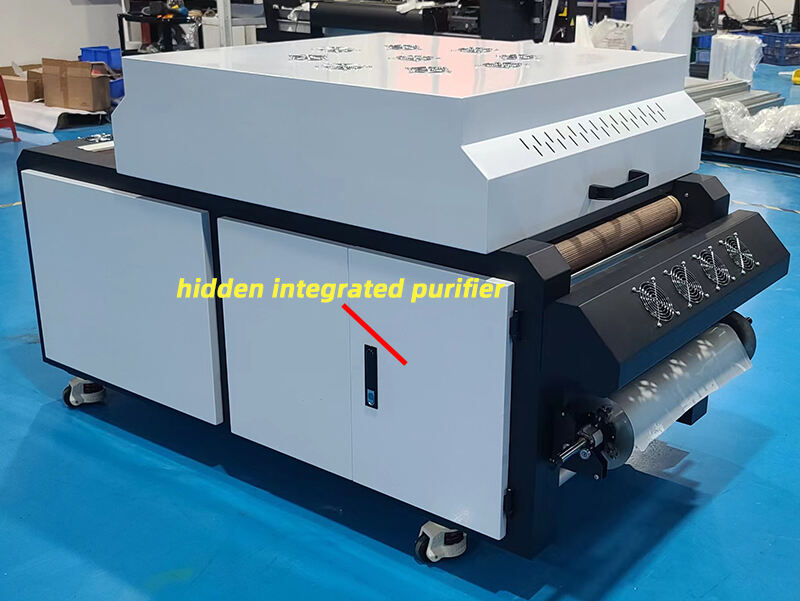

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |