XURON

The DTF Powder Shaker Machine is a must-have tool for any printing business. If you are looking for something that can help you print designs and logos on t-shirts, cups, and other items with ease, then this machine should be at the top of your list. What makes the DTF Powder Shaker Machine so special is that it incredibly easy to use. All you need to do is to pour the powder into the machine and it will do all the work for you.

The shaker was created a powerful motor enabling it to shake the powder in a manner is uniform. This ensures you employ it you will get consistent outcomes each and every time. Additionally, the apparatus has a timer that integrated one to set enough time for the process is shaking. This gives you more control over your printing procedure and assists one to have the outcomes being precise needs.

One of the best grounds for the DTF Powder Shaker Machine is it really is extremely durable. Manufactured from high-quality materials, this machine can withstand use is rigorous last for a relatively good time without needing any upkeep. This can make it an investments is certainly excellent any publishing business that would like to spend less on maintenance costs.

Another feature is certainly very good of DTF Powder Shaker Machine is its compact design. This machine can fit in any workspace without dealing with a lot of room along with its little size. This makes it and choice is certainly organizations are perfect restricted areas.

Get yours today and start taking your business to the next level?

60cm DTF machine | |

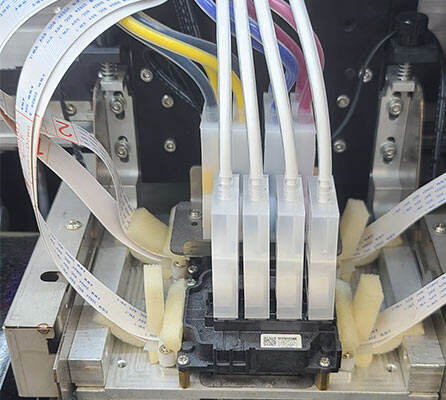

Nozzle Type | 2 original Epson I3200 |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour |

Color Mode | CMYK+W |

Print Format | 600mm-650mm |

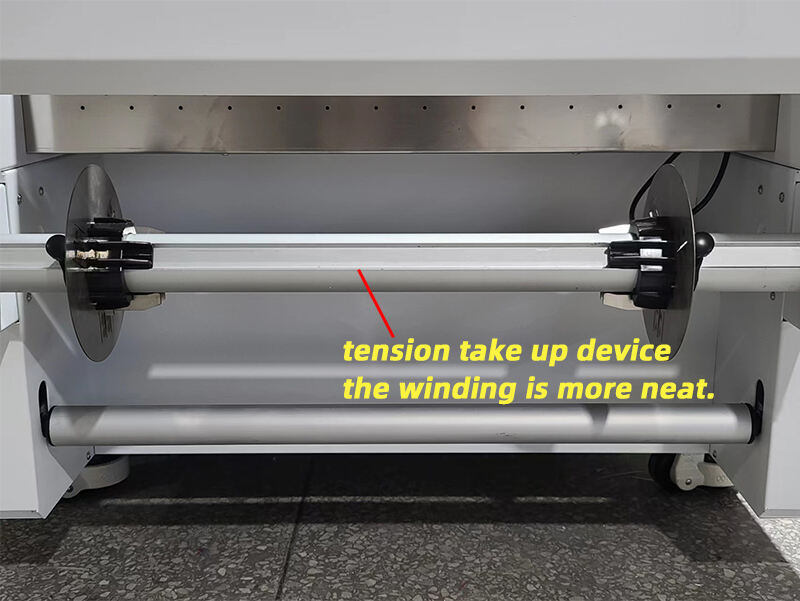

Media Transfer | Damping paper/tension paper |

Heating Equipment | Front, middle and back three-stage heating |

Power Supply | 110V/220V 50-60Hz |

Power | 1kw |

Working Environment | Temperature 20-28℃ Humidity 70% |

Ink road system | Automatic ink supply, Constant pressure circulation system |

Weight | 160KG |

Package Dimensions | 181*94*136cm cbm:2.31 |

Shake powder machine | |

Power | ≈2KW |

Shaking Powder | Motor vibration, automatic powder return-free |

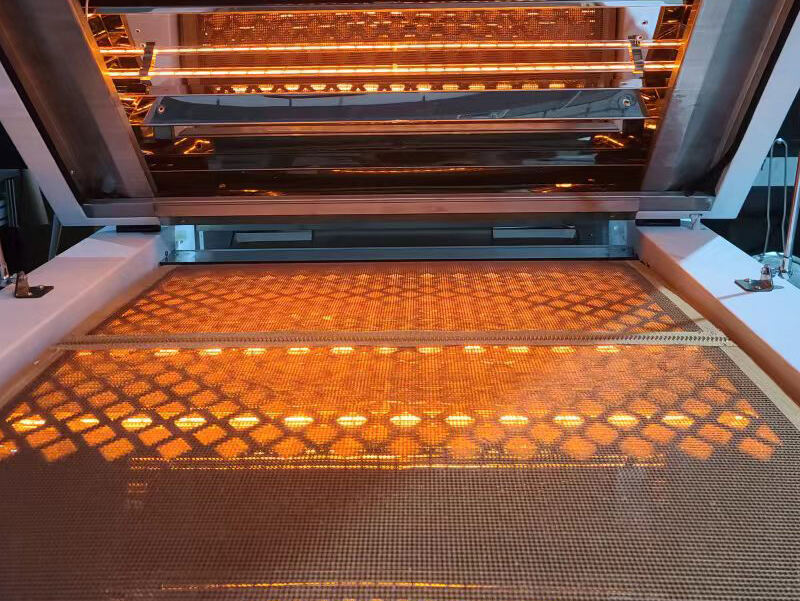

Heating Method | Back baking and front baking Fast constant temperature heating |

Take-up and Feed Film | Constant tension automatic induction system |

Operation Mode | Manual control/Auto control |

Mesh Belt | Drum suction operation mesh belt |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film |

Method of Dusting | Constant weight automatic sensing |

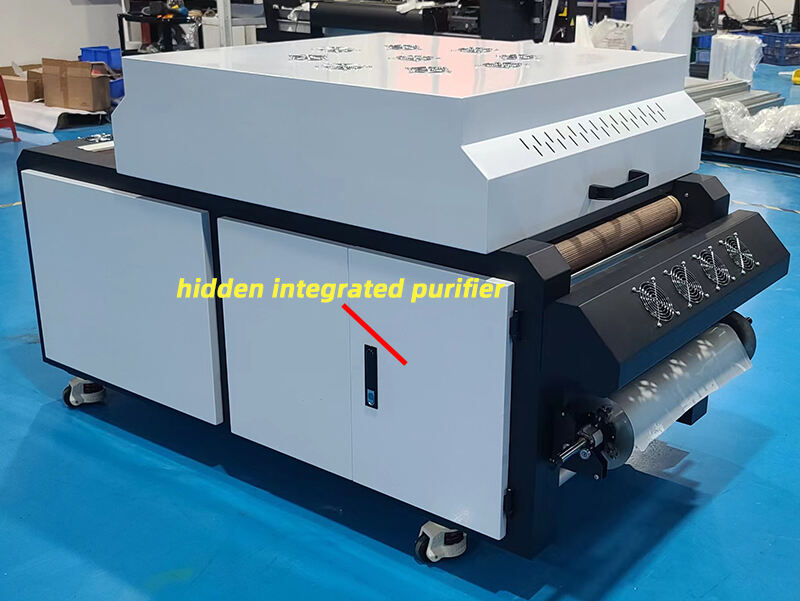

Machine Weight | 240KG |

Package Weight | 347KG |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 |

Configuration | With All-in-one smoke purifier |

TOTAL PRINTER WITH SHAKE MACHINE | |

Cover Area | 108*350cm |

The print head will be pre-installed foe customers, all parameters and calibration values will be preset in the factory, the software will be remotely installed by after-sales staff; customers only need to add ink to use the machine, the installation is safe, convenient and fast.

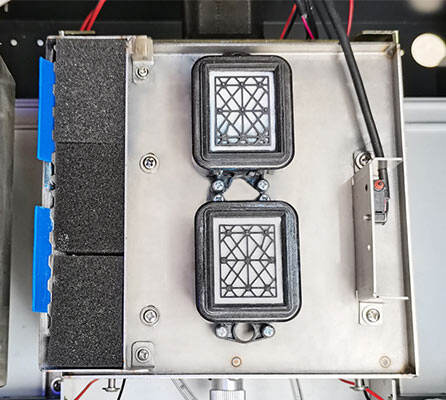

Elevation Type Capping Station New design capping system, more durable.

Constant tension paper system, the precision of the double-sided film is the same as that the single-sided measuring accurate paper feeding, the printing dots are very delicate the registering is accurate, and the light color blocks are cut and performed well.

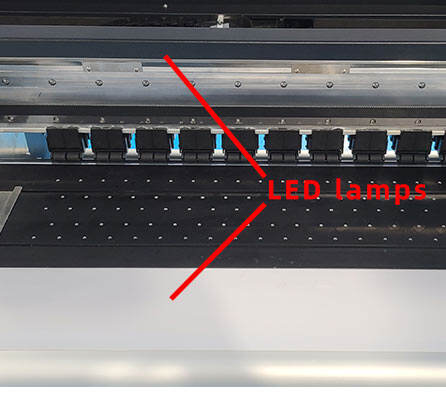

Install double-row LED lamps, check the printing situation at any time, and ensure product quality

High frequency powder shaking device, less noise better powder shaking effect, so that the final pattern will not appear white edge