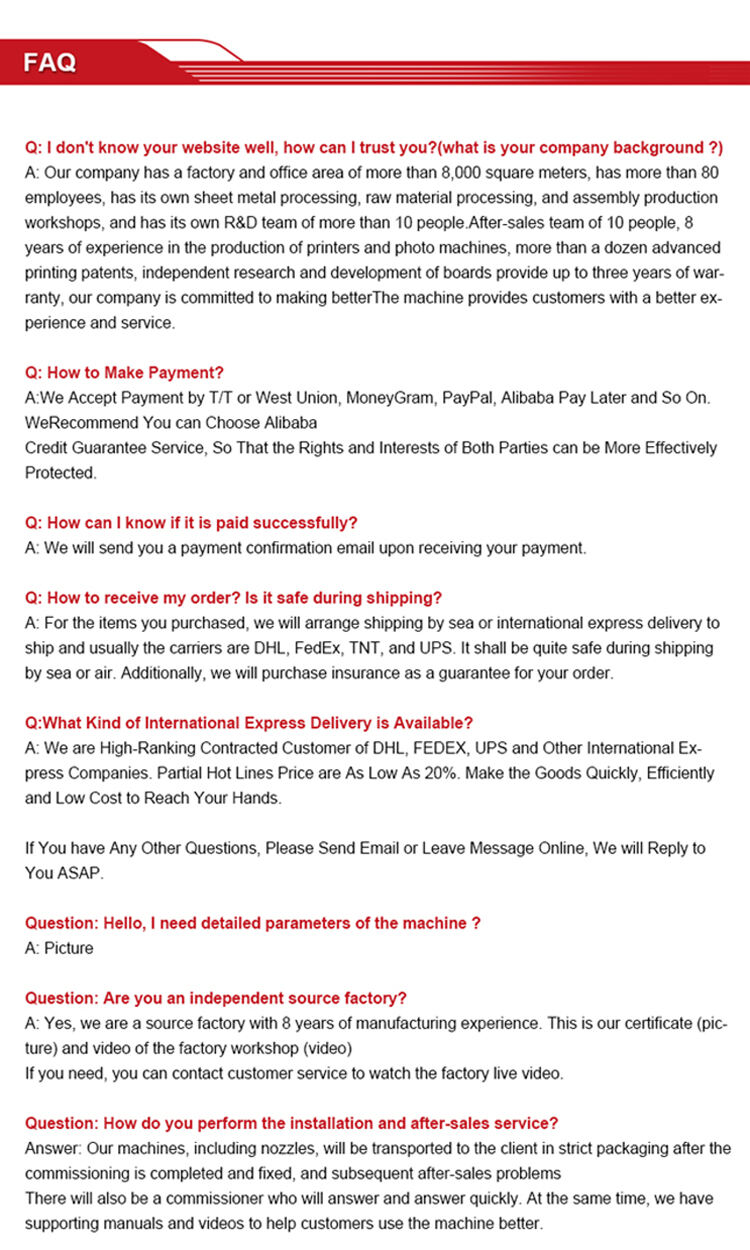

The XURON DTF Transfer Printing and Powder Shaker device is truly a strong and publishing that is versatile that provides precision that is quality that is unprecedented. This device is able to create top-quality prints that are razor-sharp, vibrant, and remarkably detailed, making it an instrument this is actually must-have any expert printer having its degree inkjet that is technology that is advanced.

Beautifully made with convenience useful in mind, the XURON DTF Transfer Printing and Powder Shaker unit is straightforward to hold and run. Its user interface this is actually permits that are intuitive effortlessly adjust printing settings, making certain each publishing is ideal and free of flaws. This printer has the ability to handle many news that is different, including paper, plastic, and textiles, which makes it an ideal option for the number of applications plus a number of advanced features.

The XURON DTF Transfer Printing and Powder Shaker unit could be extremely affordable additionally and efficient. Its inkjet that is level that is advanced that pictures are manufactured quickly and accurately, assisting users save money and time with their publishing costs. Enough reason for its powder that is shaker that is effective device has the ability to evenly distribute DTF powder onto images, ensuring each printing is vibrant and crisp, whilst also wastage this is actually keeping this is really reducing low.

The XURON DTF Transfer Printing and Powder Shaker device is in fact a product that is top-tier's certain to meet with one of the most demanding publishing requirements alongside its sleek design, durable construction, and precision that is unrivaled. This device is just an investment that is wonderful particular to boost your publishing quality, effectiveness, and efficiency whether you might be a printer that is expert a hobbyist.

60cm DTF machine | ||

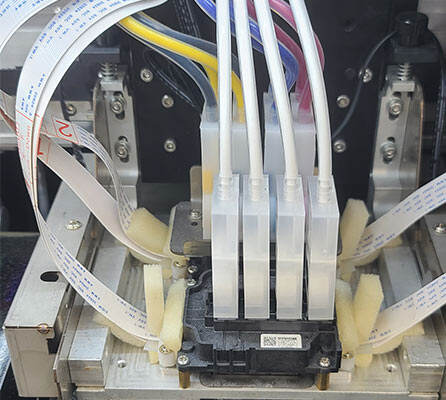

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

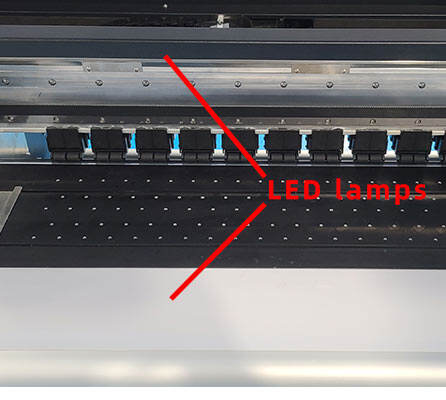

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

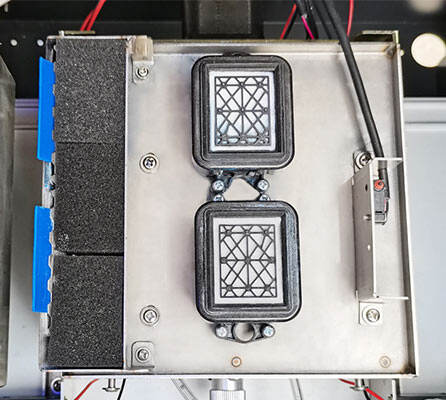

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

Shaking Powder | Motor vibration, automatic powder return-free | |

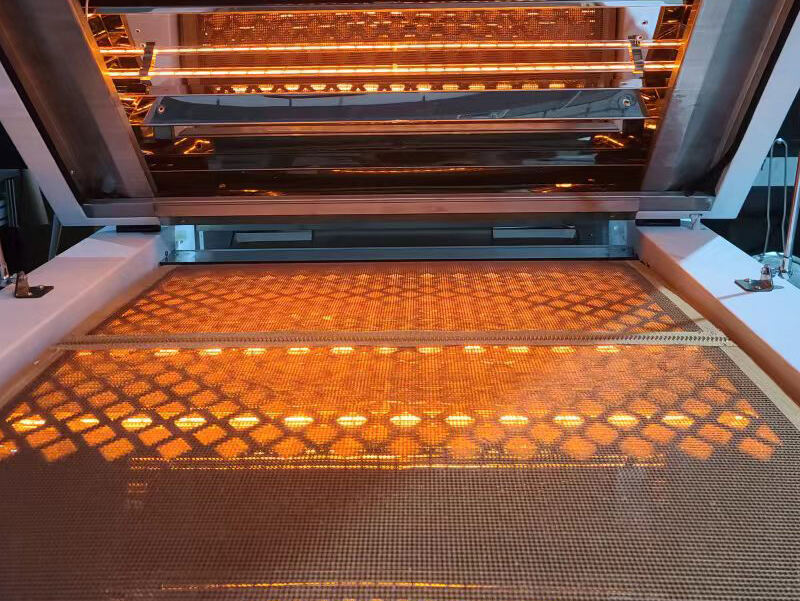

Heating Method | Back baking and front baking Fast constant temperature heating | |

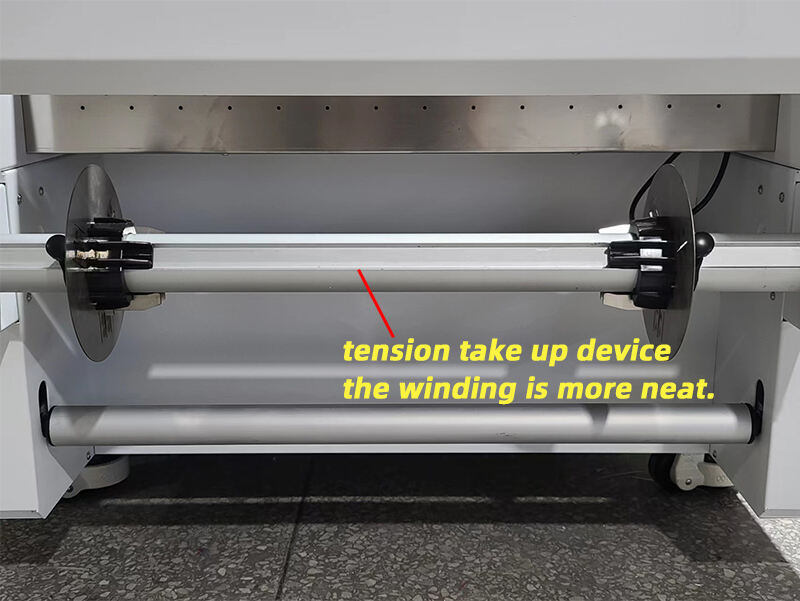

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

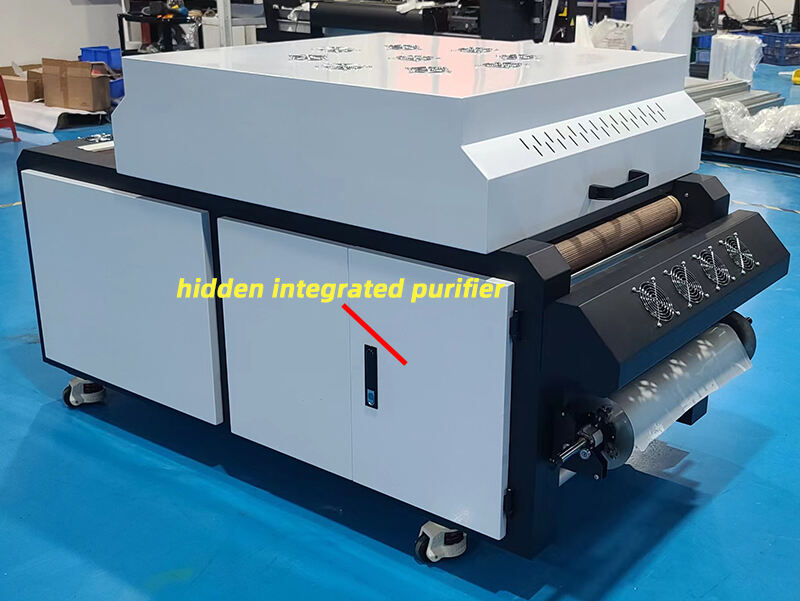

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |