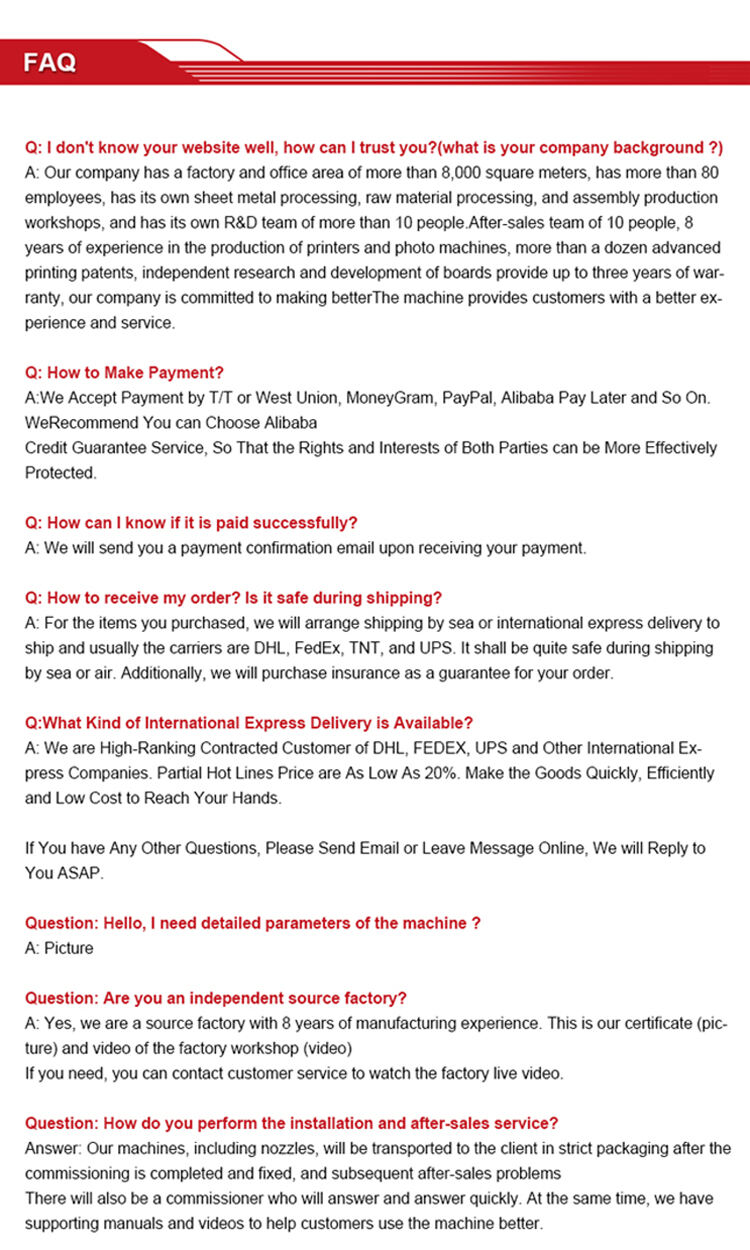

XURON Heat Press Machines Printing dtf may be an alternative this is often people who are definitely want that is fantastic create their customized tees, bags, caps, and even more. These devices utilize the direct-to-fabric this is really latest (dtf) printing technology, which makes it a facile task to transfer top-quality designs onto many different materials.

One of the most significant advantages of the XURON Heat Press Machines Printing dtf may be the flexibility. They can print on an array of materials and materials, including cotton, polyester, also leather based. You can actually take advantage of them to produce designs which can be modified caps, bags, and also other add-ons. This could make them perfect for smaller organizations, DIY enthusiasts, along with hobbyists who wants to create personalized items by themselves or other individuals.

Just one more thing that sets XURON Heat Press Machines Printing dtf apart from other publishing devices could be the simpleness. They will have instructions which are easy-to-follow causes it to be a task this is really simple also start for newbies. The settings which are electronic simple and easy intuitive to navigate, to assist you set the heat, time, and anxiety to achieve the publishing this is really perfect.

This is really mainstream could be the quality linked to publishing among the list of simple things that are excellent XURON Heat Press Machines Printing dtf compared to publishing. The colors and details are far more vibrant and thought as the ink is sent straight to the material. And thus, you can produce designs which can be simplicity that is intricate as well as your finished things can look top-notch and expert.

XURON Heat Press Machines Printing dtf are extremely durable and dependable. They have been fashioned with top-notch materials and intended to withstand use that is time that is definitely hefty. Meaning for the right time that is very long worrying about breakage or breakdown you need to use them.

60cm DTF machine | ||

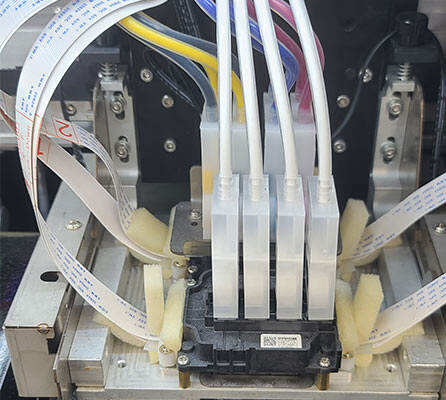

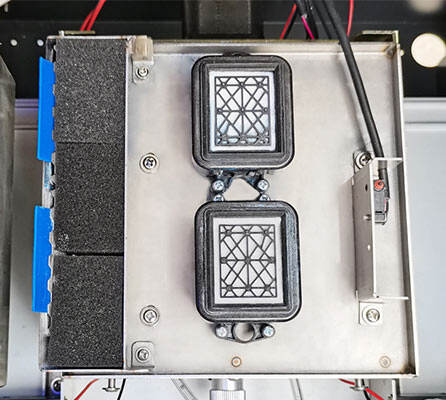

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

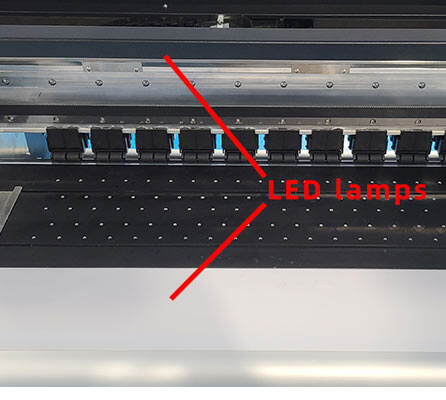

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

Shaking Powder | Motor vibration, automatic powder return-free | |

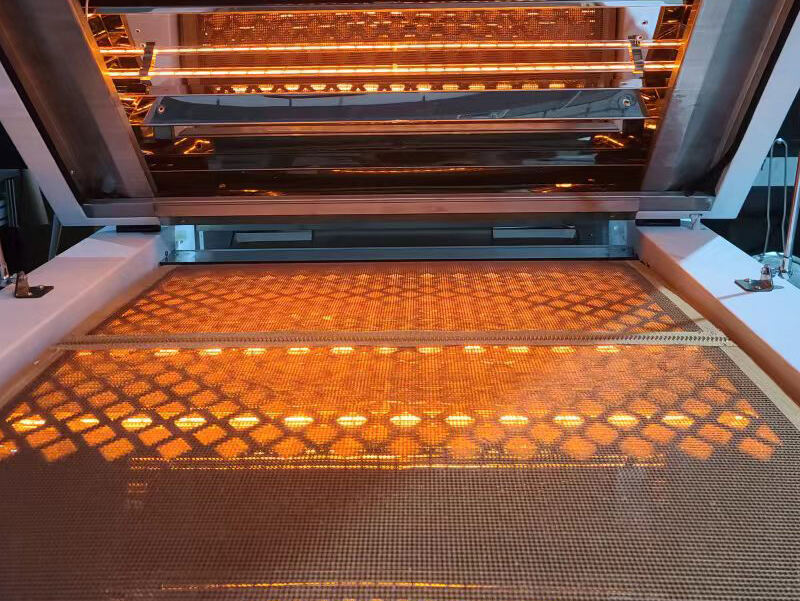

Heating Method | Back baking and front baking Fast constant temperature heating | |

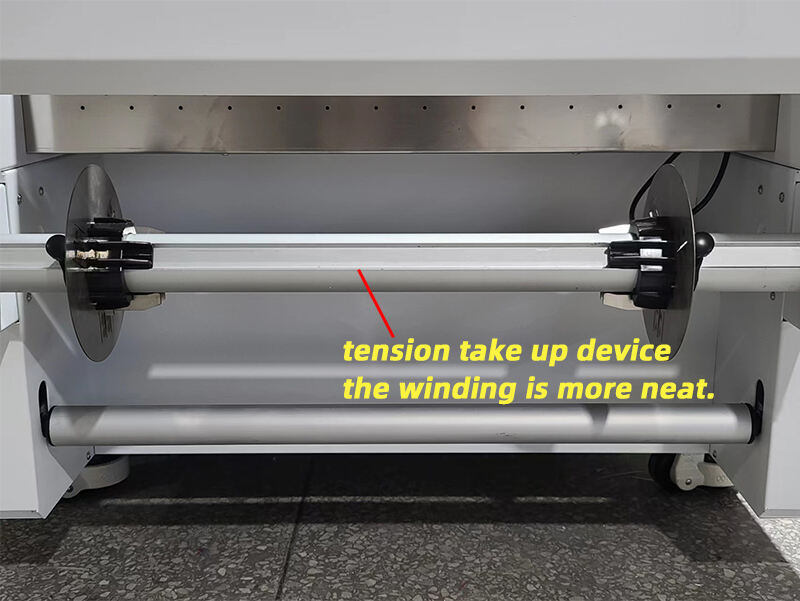

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

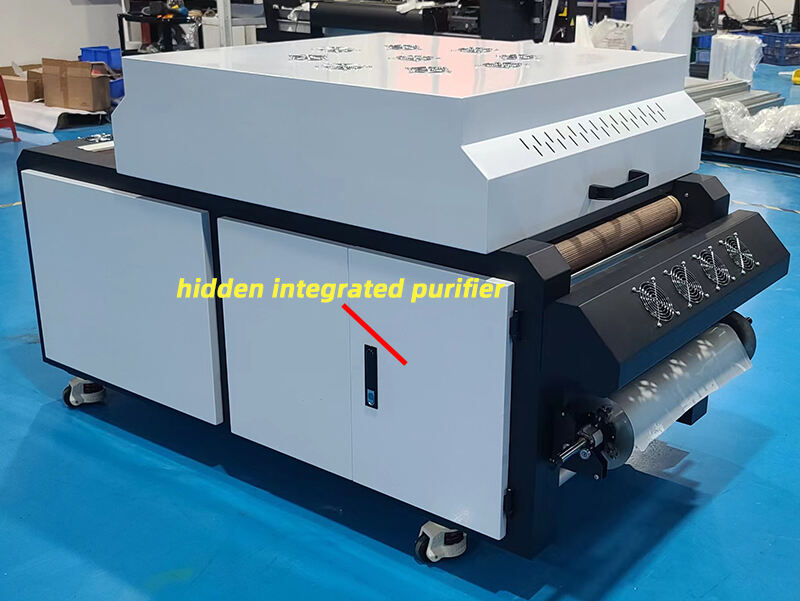

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |