Presenting the XURON Printer for Textiles - the energy this is certainly DTF that is low that revolutionizes the entire realm of textile publishing. This printer this is certainly top-quality unparalleled dependability and cost-efficiency, making it your best option for small enterprises, businesspeople, and textile enthusiasts alike.

The XURON Printer for Textiles is a cutting-edge, superior printer this is certainly DTF is built to manage an array of textile applications. It features an energy this is certainly low design, which allows you to save yourself energy and minimize running costs while nevertheless enjoying the advantages of top-quality publishing.

Designed with top-of-the-line technology, this printer uses pigmented ink and transfers it on the surface that is textile the help of stress and temperature. The outcome? Bright, durable, and fade-resistant prints that look final and great long.

The XURON Printer for Textiles is not hard to make use of, also for first-time users. The interface that is intuitive design that is user-friendly it a facile task to make use of and maintain, helping you save money and time on printer upkeep and upkeep.

You covered whether you would need to print on t-shirts, hats, bags, or any other textiles, the XURON Printer for Textiles has. It offers print this is certainly exceptional for a number of materials, including cotton, polyester, and combinations, to mention just a couple of.

So why select the XURON Printer for Textiles? Every time to begin with, this is certainly a dependable and tool that is efficient delivers consistent outcomes. It is easy to utilize and a task that is easy maintain, which makes it the decision this is certainly perfect companies of all of the sizes.

The XURON Printer for Textiles may be a good investment which will repay in the end using its low power usage design and high-quality print output. You'll need if you want to just take your textile printing to another location level, this is basically the printer.

60cm DTF machine | ||

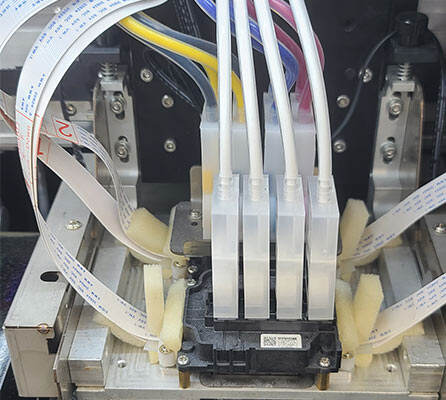

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

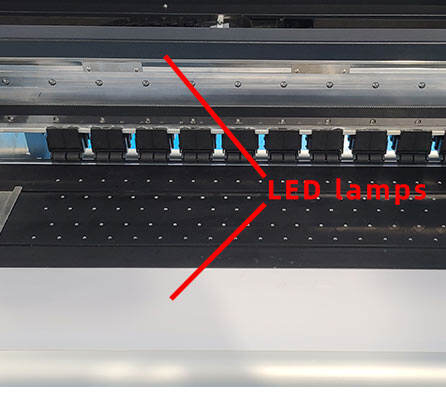

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

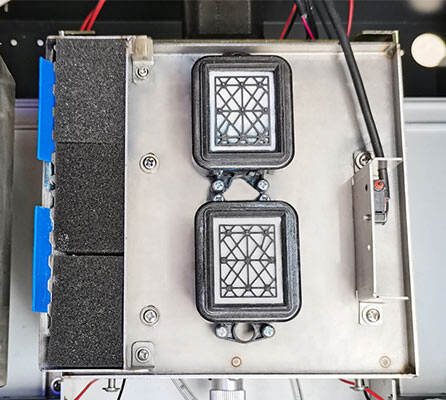

Shaking Powder | Motor vibration, automatic powder return-free | |

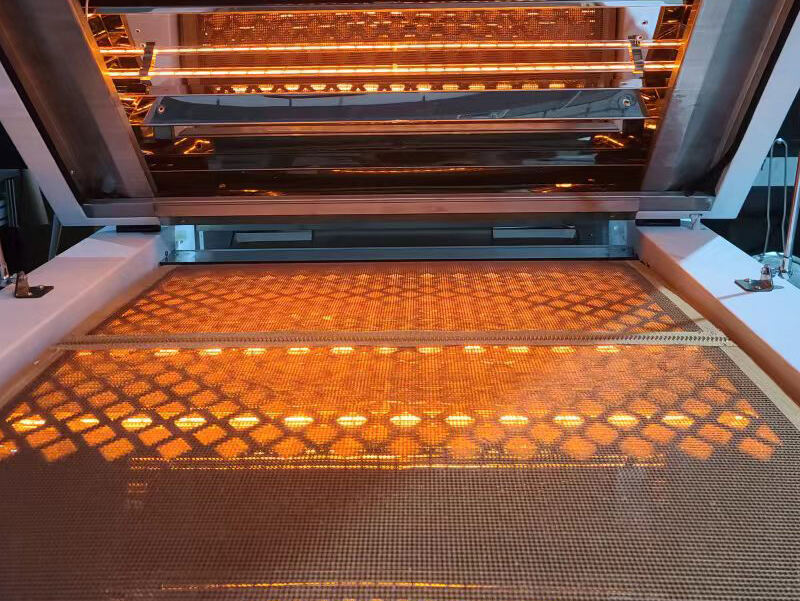

Heating Method | Back baking and front baking Fast constant temperature heating | |

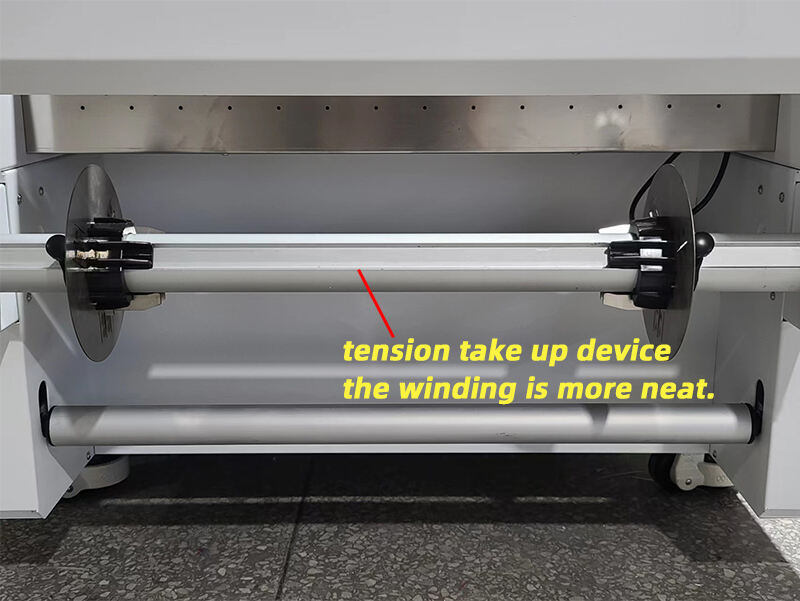

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

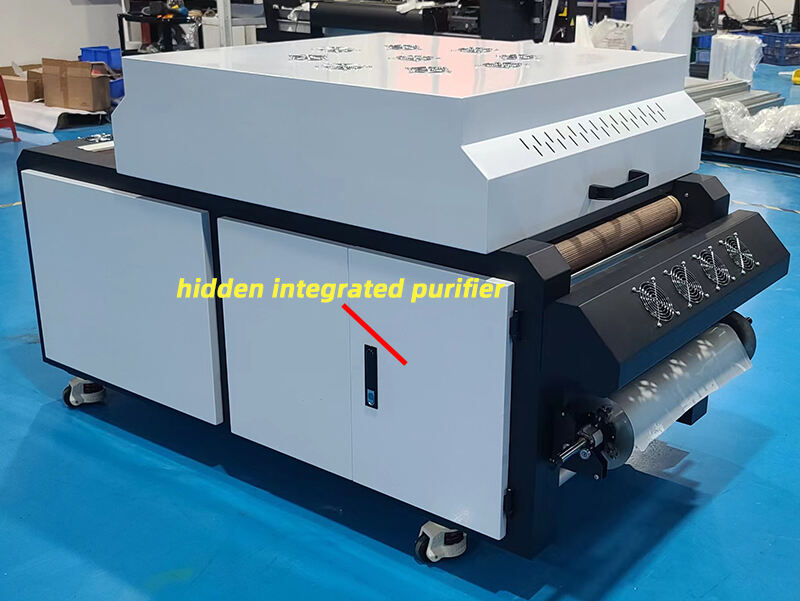

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |