Brand: XURON

XURON T-shirt Printing with DTF Technology Powder Shaker machine may end up being the solution that is ideal your t-shirt this is certainly personalized printing. You covered whether you’re a company this is certainly little attempting to create custom product that is branded or maybe an individual attempting to make an unusual gift, the product has.

The DTF technology present in the product is brief for Direct to Film, this means the appearance is printed onto a thin, transparent movie that is definitely then heat transmitted on the material. That way of publishing is superior to make screen this is really conventional because it provides greater accuracy in relation to of design, color accuracy, and image positioning.

The powder shaker feature concerning the XURON T-shirt Printing with DTF tech device is truly exactly what actually sets it as well as other products that are similar industry. This aspect this is certainly particular the application form this is certainly easy of powder this could be undoubtedly special is required for the printing process. The shaker signifies that the powder is distributed evenly and precisely throughout the movie this is actually entire producing a transfer that is top-quality is sure to impress.

The XURON T-shirt Printing with DTF Technology Powder Shaker Machine is hugely user-friendly. It offers a simple and control this is certainly easy is intuitive that permits you to definitely effortlessly pick the desired print settings and modify your designs. The item may be compact and lightweight, making this an easy task to keep and maneuver.

The XURON T-shirt Printing with DTF tech Powder Shaker device could be developed to additionally that is also last its impressive performance abilities. It undoubtedly is manufactured far from top-notch materials that will withstand use this is use this is certainly obviously constant tear.

60cm DTF machine | ||

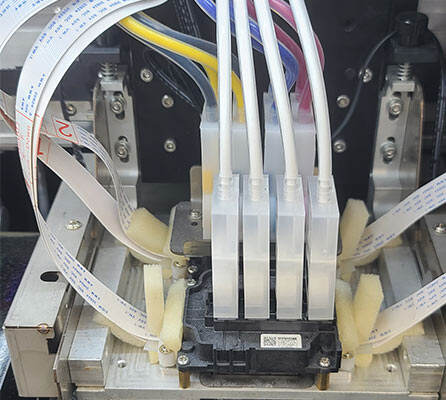

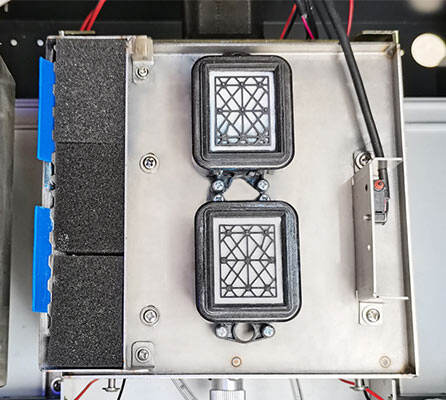

Nozzle Type | 2 original Epson I3200 | |

Nozzle Type(interweave printing program) | 1 original EPSON I3200(8)-A1 1 original EPSON I3200(4)-A1 | |

Printing Speed | 4 pass 720*1200 :High speed mode 15m²/hour 6 pass 720*1800 :HD mode 10m²/hour 8 pass 720*2400 :HD mode 8m²/hour | |

Printing Speed(interweave printing program) | 4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour | |

Color Mode | CMYK+W | |

Print Format | 600mm-650mm | |

Media Transfer | Damping paper/tension paper | |

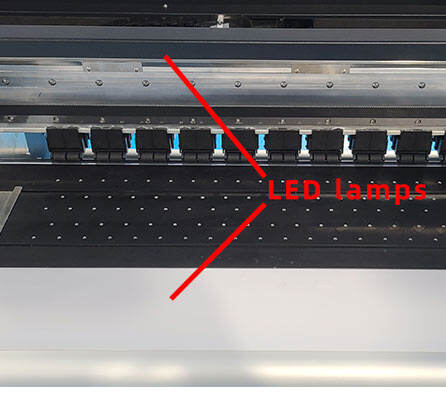

Heating Equipment | Front, middle and back three-stage heating | |

Power Supply | 110V/220V 50-60Hz | |

Power | 1kw | |

Working Environment | Temperature 20-28℃ Humidity 70% | |

Ink road system | Automatic ink supply, Constant pressure circulation system | |

Weight | 160KG | |

Package Dimensions | 181*94*136cm cbm:2.31 | |

Shake powder machine | ||

Power | ≈2KW | |

Shaking Powder | Motor vibration, automatic powder return-free | |

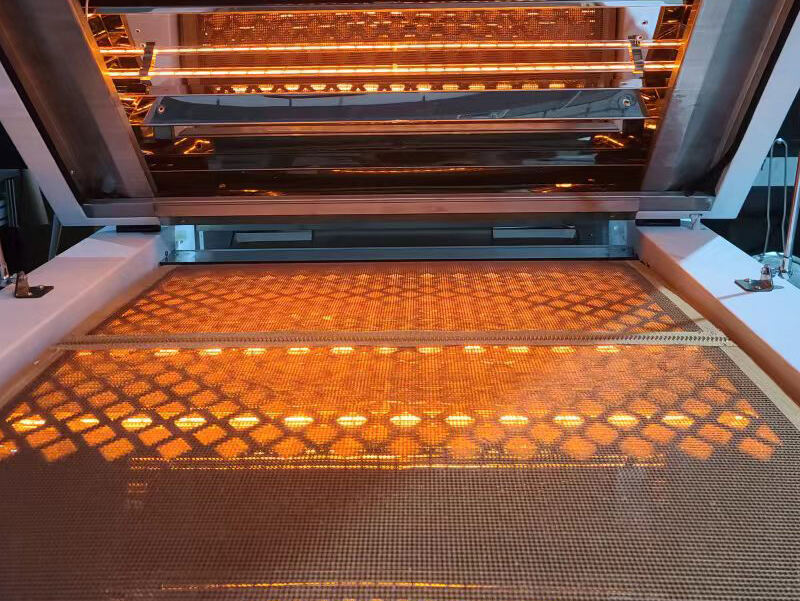

Heating Method | Back baking and front baking Fast constant temperature heating | |

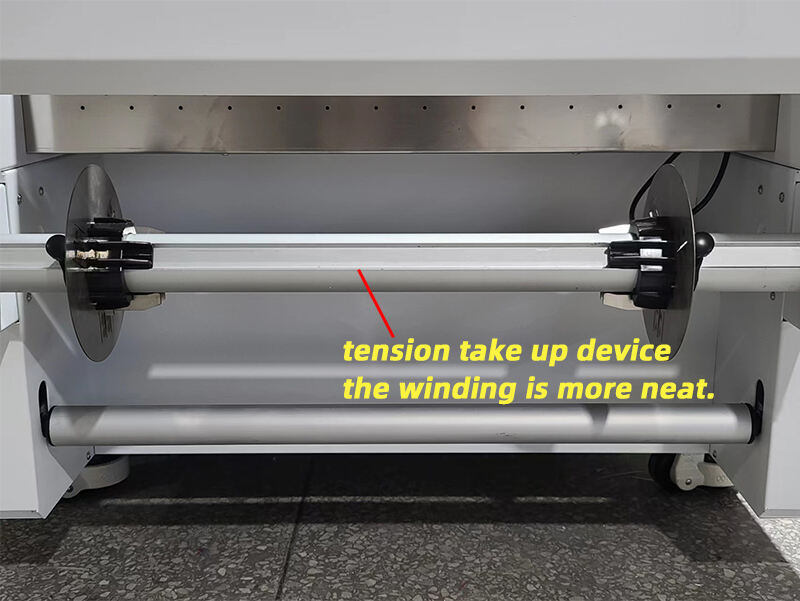

Take-up and Feed Film | Constant tension automatic induction system | |

Operation Mode | Manual control/Auto control | |

Mesh Belt | Drum suction operation mesh belt | |

Automatic Deceleration of Film Cutting | Prevent deformation of heating film | |

Method of Dusting | Constant weight automatic sensing | |

Machine Weight | 240KG | |

Package Weight | 347KG | |

Package Dimensions | 193*114.5*110.5cm cbm:2.44 | |

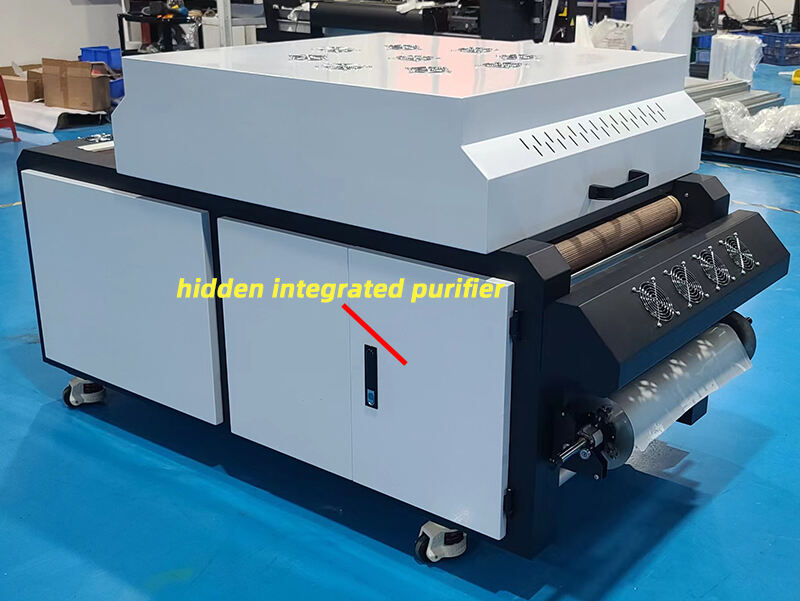

Configuration | With All-in-one smoke purifier | |

TOTAL PRINTER WITH SHAKE MACHINE | ||

Cover Area | 108*350cm | |